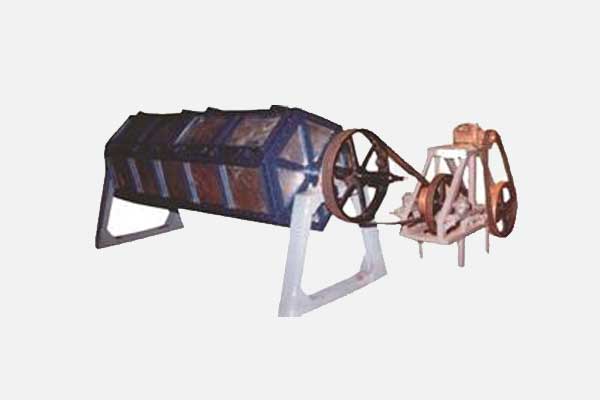

Roasters (Hexagonal)

Design:

- Roaster: It is designed in such a way that steam enters through the both ends of the perforated shaft in which Roaster is fixed. Roaster rotates at a speed of 24 R.P.M.Shaft ends are coupled with Rotating Union.Rotating Union is such a unit that its one end rotates with the staff and other part is fixed with the steam delivery line.

- Drive Unit: This unit is a speed reducing unit.5 H.P.440 V.3 PH. 1440 R.P.M. motor is used in the unit with different size belts so as to reduce the speed from 1440 R.P.M.to 24 R.P.M.i.e.60:1 ratio.

Capacity

100 kg/hr, 200kg/hr.

Use

It is an essential item used in Tea Gardens for manufacturing Green Tea.

Operation

After filling the Roaster with green leaves of 100 kg directly plucked from garden, doors of the roaster are closed and switched for rotating, consequently steam lines are opened. Steaming continues for 6 to 7 minutes and within this time the leaves are boiled. If the leaves are not tender i.e. plucking after 7 days then time of ousting will go up by one minute to one and a half minute.

Profitability

In old days the Tea Gardens boiled the green leaves by hot water .Some gardens also follow this procedure till date but in this process quality and percentage of made tea is not up to the mark comparing with the new process. Barring inferior quality only 18% to 19% made tea is achieved in this process, but by using Roaster with steam high quality tea with 25% made tea is achieved,i.e a gain of 6% to 7% in weight with superior quality.